NORBIDAR stands out among fumaric acid manufacturers for producing high-quality fumaric acid with exceptional expertise. When it comes to how is fumaric acid made, the process primarily involves microbial fermentation, with Rhizopus species such as Rhizopus nigricans and Rhizopus arrhizus playing a key role. Additionally, Bacillus sp. MI-105 contributes to the efficient production of fumaric acid. This versatile compound is widely used across various industries and is a common ingredient in many fumaric acid foods. Each year, a significant amount of fumaric acid is produced, with nearly 85% coming from microbial fermentation. For those curious about how is fumaric acid made, the answer lies in the advanced use of microbes to achieve high purity and quality.

Key Takeaways

- Rhizopus species, like Rhizopus arrhizus, are the main microbes used to make fumaric acid. They give a high amount and work well. Bacillus sp. MI-105 helps make fumaric acid in different ways. It lets people use other methods and settings. Making fumaric acid with microbes is good for the environment. It uses plants and does not need fossil fuels. NORBIDAR uses special fermentation to make pure fumaric acid. This keeps the quality high and meets what industries need. Fumaric acid is used in food, medicine, and industry. It is important in many markets.

Microbes used in fumaric acid production

Rhizopus species as primary producers

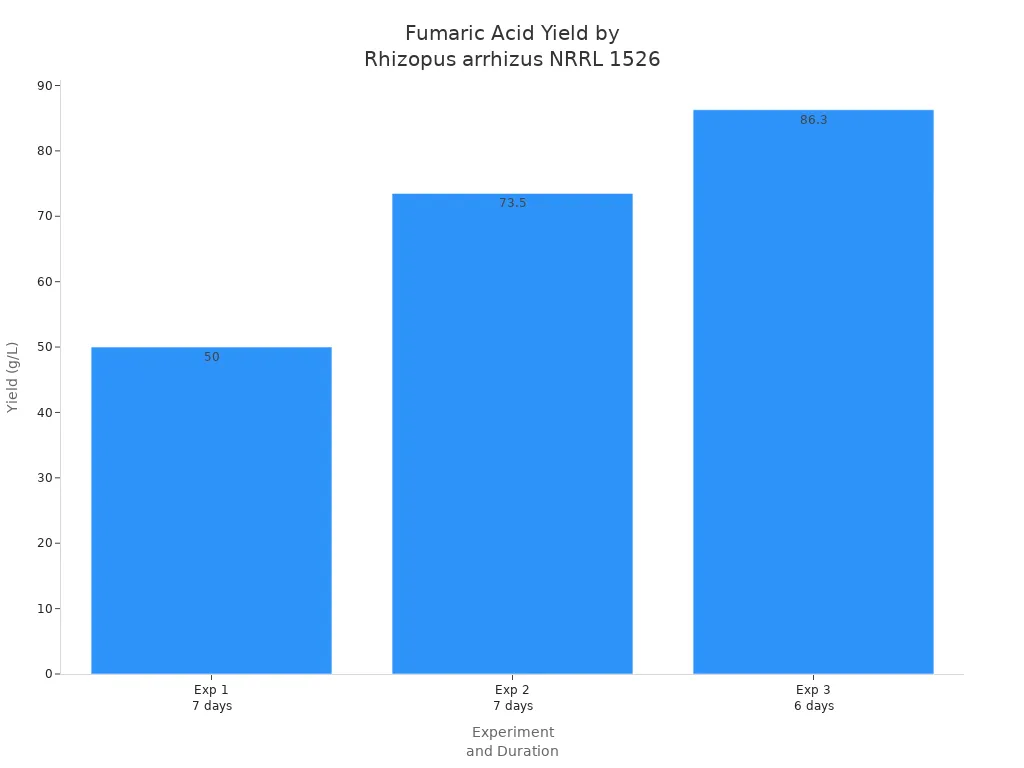

Rhizopus species are very important for making fumaric acid. Many scientists and companies pick Rhizopus arrhizus and Rhizopus nigricans. These fungi can make a lot of fumaric acid. Rhizopus arrhizus NRRL 1526 is known for working well. The table below shows how much fumaric acid this fungus makes in different tests:

| Rhizopus Species | Production Yield (g/L) | Yield (g/g) | Duration (days) |

|---|---|---|---|

| Rhizopus arrhizus NRRL 1526 | 50 | 0.44 | 7 |

| Rhizopus arrhizus NRRL 1526 | 73.5 | 0.55 | 7 |

| Rhizopus arrhizus NRRL 1526 | 86.3 | 0.67 | 6 |

Rhizopus arrhizus grows well on loofah fiber in special tanks. This setup gives the fungus air and food. It helps the fungus make more fumaric acid. Rhizopus species use a pathway called cytosolic reductive TCA pathway. When there is not much nitrogen, this pathway helps the fungus work better. Scientists can change the medium and temperature to get more fumaric acid.

Role of Bacillus sp. MI-105 in production

Bacillus sp. MI-105 also helps make fumaric acid. This bacterium works in a different way than Rhizopus species. Bacillus sp. MI-105 can live in many places. It makes the process more flexible. Some companies use Bacillus sp. MI-105 to make more fumaric acid or try new ways to produce it. This microbe gives the industry another choice for making this compound.

Scientific classification and characteristics

Rhizopus nigricans and Rhizopus arrhizus are part of the kingdom Fungi. Both have similar traits and belong to the same group. The table below shows their scientific names and main features:

| Classification Level | Rhizopus nigricans | Rhizopus arrhizus |

|---|---|---|

| Kingdom | Fungi | Fungi |

| Phylum | Zygomycota | Zygomycota |

| Order | Mucorales | Mucorales |

| Family | Mucoraceae | Mucoraceae |

| Genus | Rhizopus | Rhizopus |

| Morphological Features | Dark greyish-brown color, 10mm high rhizoids, 100 micrometre sporangia | Dark greyish-brown color, 10mm high rhizoids, 100 micrometre sporangia |

Tip: Rhizopus species look dark greyish-brown. They grow rhizoids up to 10mm tall. Their sporangia are about 100 micrometers wide. These things help scientists know which fungus they have.

Bacillus sp. MI-105 is part of the kingdom Bacteria. This microbe looks very different from Rhizopus species. Bacillus sp. MI-105 has a rod shape. It can live in many kinds of places.

Rhizopus species have been used for a long time to make fumaric acid in factories. Their genes and ability to work in different conditions make them great for big production. Companies like NORBIDAR use these microbes to get lots of fumaric acid and keep the quality high.

Why Rhizopus is Preferred

High yield and efficiency

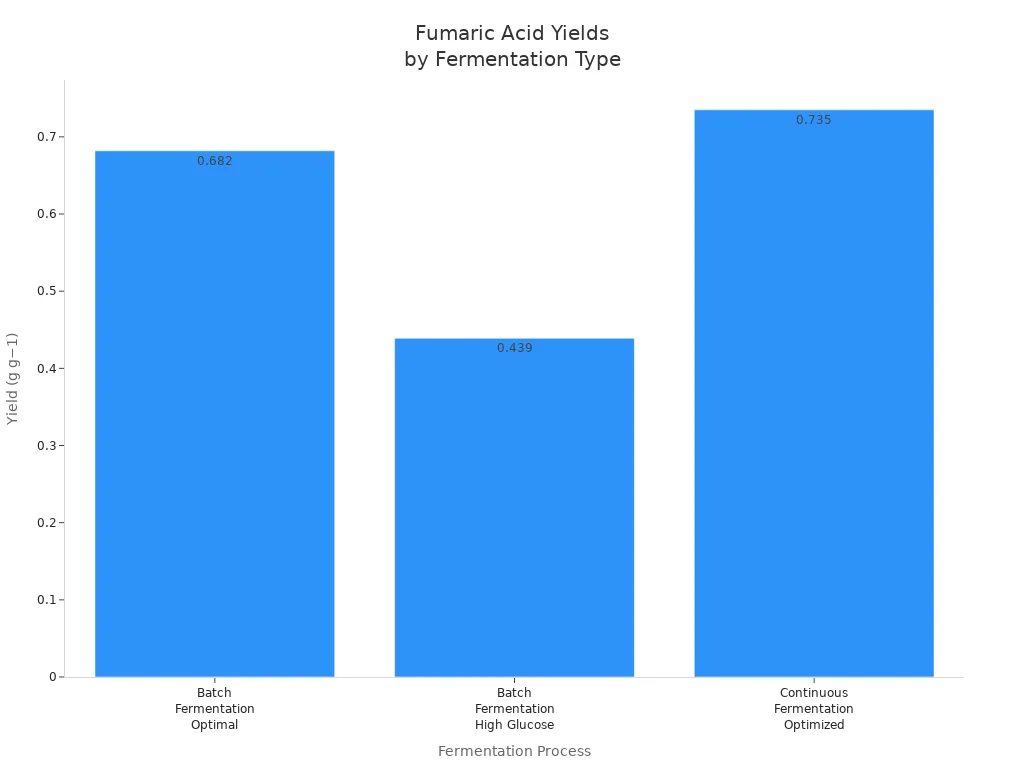

Rhizopus species can make a lot of fumaric acid. Many factories pick these fungi because they give high yields. They work well in batch and continuous fermentation. The table below shows how much fumaric acid Rhizopus makes in different ways:

| Process Type | Yield (g/g) | Notes |

|---|---|---|

| Batch Fermentation | 0.682 | Highest yield on xylose under optimal conditions. |

| Batch Fermentation | 0.439 | Yield drops with high glucose due to ethanol production. |

| Continuous Fermentation | 0.735 | Best yield when process favors fumaric acid over ethanol. |

Rhizopus species use simple nutrients. They can break down starchy things right away. This makes the process easier and costs less. These fungi can handle fermentation inhibitors. They work well in many places.

Safety and regulatory acceptance

Safety matters for food and medicine. Fumaric acid from Rhizopus has passed many safety checks. The table below shows important results:

| Safety Aspect | Findings |

|---|---|

| Acute Toxicity | Low toxicity; high safe dose in animal studies. |

| Irritation | Mild skin and moderate eye irritation, effects are reversible. |

| Chronic Exposure Effects | Minor stomach upset in some cases. |

| Carcinogenic Classification | Not carcinogenic; no evidence of causing cancer. |

| Acceptable Daily Intake (ADI) | No health risk at normal use levels. |

| Metabolism | Quickly broken down in the body. |

Groups that check safety have approved Rhizopus fumaric acid for food, feed, and medicine. This helps companies and people trust that it is safe.

Adaptability to industrial fermentation

Rhizopus species can adjust to many factory needs. They grow on lots of raw materials, even farm leftovers. Factories use them in small or big fermenters. Rhizopus molds like R. oryzae and R. oligosporus work well in food and chemical factories.

NORBIDAR uses special biosynthesis and controls to get great results with Rhizopus. These methods help make pure fumaric acid for many things, like food and plastics. Their flexible way lets them meet new market needs and keep quality high.

Tip: Rhizopus species can handle changes in temperature, pH, and substrate. This makes them good for steady production.

Industrial process for producing fumaric acid

Fermentation steps and conditions

NORBIDAR makes fumaric acid using a special fermentation process. First, workers grow Rhizopus species in tanks filled with liquid. They add nutrients and set the right temperature and air. The fungus Rhizopus oryzae grows based on the starter size and the medium. If the fungus grows too fast, it forms big clumps. These clumps are not good for making fumaric acid. The process uses a 10-liter bubble column fermentor. This machine can make more than 80% yield. It also produces about 1.2 grams per liter per hour when limestone is added. NORBIDAR controls how much glucose goes in and keeps the pH steady. They also watch for ethanol by-products to get the best yield and purity.

Substrates and optimal environments

Glucose is the main food for the fungus in fermentation. Other foods like glycerol, xylose, and sucrose have been tried. Glucose works the best for making fumaric acid. The best conditions are a pH of 3.5, a temperature of 30°C, and air at 1.5 VVM.

| Parameter | Optimal Value |

|---|---|

| pH | 3.5 |

| Temperature | 30°C |

| Aeration | 1.5 VVM |

NORBIDAR uses these settings to get high yields and good quality every time.

Downstream processing and purification

After fermentation, NORBIDAR cleans and purifies the fumaric acid. First, they remove big particles and fungus cells. Next, they separate fumaric acid from the liquid and other stuff. Sometimes, they change salts into acid form. Then, they concentrate and purify the product to make it stronger and cleaner. NORBIDAR uses special methods like Simulated Moving Bed (SMB) technology. This method helps get purity above 99% and keeps yields high. Careful checks at each step help NORBIDAR make sure the fumaric acid is always high quality.

Note: NORBIDAR checks every step closely to keep the product pure and meet industry rules.

Microbial Fumaric Acid: Pros and Cons

Benefits over chemical synthesis

Making fumaric acid with microbes has many good points. Companies use plant sugars like glucose, not oil. This helps save fossil fuels. Microbial methods can get up to 85% yield from glucose. This is a high amount. The process is better for the earth. It uses less oil and more plant waste. Using plant waste means less trash and less pollution. This helps the planet stay cleaner.

- Uses plant-based resources that can grow again

- Gets high yields from glucose

- Needs less fossil fuel

- Uses plant waste, so less is thrown away

- Makes less pollution

NORBIDAR works hard to protect the environment. They use smart ways to make good products and care for nature.

Challenges in large-scale production

Making lots of fumaric acid with microbes is not easy. Factories must watch how the fungus grows. They need to keep the process steady. The food for the microbes changes how fast they work. It also affects how long the machines last. Oxygen is important for healthy cells and good results. Factories want to make more product in less time. They also want higher yields for success.

| Challenge | Description |

|---|---|

| Fungal Morphology and Physiology | Factories must control how the fungus grows for steady output. |

| Medium Composition | The right food helps the process go faster and keeps machines working. |

| Oxygen Transfer Rates | Good oxygen flow keeps cells healthy and helps them make more. |

| Reactor Volumetric Productivity | Making more product at once saves money. |

| Product Yield and Concentration | Higher yields and stronger product are needed for big factories. |

Small tests in special tanks help companies learn what works best. NORBIDAR uses these tests to keep their process steady and get good results.

Innovations and future prospects

New technology keeps making microbial production better. Scientists try to make microbes that give more product. They change how fermentation works to get better results. They also pick the best foods for the microbes. This saves money and makes the process faster.

| Technological Innovation | Description |

|---|---|

| Strain Improvement | Better microbes make more product and help factories grow. |

| Fermentation Process Optimization | Changing things like oxygen levels helps get more fumaric acid. |

| Substrate Selection | Picking the right raw materials saves money and boosts results. |

NORBIDAR spends money on research to stay ahead. They care about quality and the environment. This helps them lead in making microbial fumaric acid.

Applications and market impact of fumaric acid

Uses in food, feed, and personal care

Fumaric acid is found in many things we use daily. It is in foods, drinks, animal feed, and personal care items. It helps make food taste better and last longer. Bakers use it to improve bread and cakes. Juice makers add it for a fruity taste. In jams and jellies, it keeps the texture smooth and the color bright. Animal experts use it to help animals digest food and grow strong. Personal care brands put it in skin and hair products for gentle cleaning and conditioning.

| Product Category | Application Description |

|---|---|

| Food | Adds flavor and acts as a preservative in many foods |

| Animal Nutrition | Improves digestion and growth in animal feed |

| Personal Care | Used in cosmetics for skin and hair benefits |

| Bakery Products | Enhances flavor and texture in baked goods |

| Jams and Jellies | Improves texture and extends shelf life |

| Beverages | Adds tartness and stability to drinks |

| Hair and Skin Care | Used in gentle exfoliating and conditioning products |

| Makeup | Helps with texture and stability in cosmetics |

Note: Fumaric acid is used in over 40% of food and drink processing. The food grade type makes up more than half of the market. This shows how important it is for keeping food fresh.

Industrial and pharmaceutical applications

Factories use fumaric acid to make many useful products. It helps make special resins for coatings and building things. Plastic makers use it to make plastics stronger and more flexible. Doctors use it in medicines for skin and nerve problems. It is also in drugs for malaria and pain. Cosmetic companies use it because it helps protect skin.

- Used in special resins for coatings and construction

- Helps make plastics and plasticizers

- Included in medicines for skin and nerve problems

- Improves animal feed for better health

- Found in cosmetics for skin protection

NORBIDAR’s role in global supply

NORBIDAR is a top company that sells high-quality fumaric acid. They help food, drink, animal feed, medicine, and factory markets. NORBIDAR uses advanced methods to make sure their product is pure and safe. Their fumaric acid helps people all over the world make better food, safer medicine, and stronger materials.

| Market Segment | Contribution |

|---|---|

| Food | Supplies fumaric acid for food use |

| Beverage | Supplies fumaric acid for beverages |

| Animal Nutrition | Supplies fumaric acid for animal feed |

| Pharmaceuticals | Supplies fumaric acid for medical use |

| Industrial Uses | Supplies fumaric acid for industrial needs |

Tip: NORBIDAR is trusted because they make good products and work with many industries around the world.

Rhizopus species and Bacillus sp. MI-105 help make fumaric acid in a way that is good for the planet. Studies show Rhizopus works better in biofilm reactors. It can also handle changes in the environment. NORBIDAR uses smart ways to make sure their fumaric acid is high quality.

- The world market for fumaric acid may reach USD 1,500 million by 2035.

- More people want fumaric acid for food, medicine, and eco-friendly uses.

- New places like Asia-Pacific and Latin America are helping the market grow.

FAQ

What is fumaric acid used for?

Fumaric acid makes food taste better and last longer. It helps animals stay healthy when added to their feed. It also makes plastics and resins stronger. Many companies put it in personal care items and medicine.

Which microbe makes most commercial fumaric acid?

Rhizopus species, like Rhizopus arrhizus and Rhizopus nigricans, make most commercial fumaric acid. These fungi are good at growing in factories.

Is microbial fumaric acid safe for food?

Food safety groups say microbial fumaric acid is safe. It goes through many tests to check purity and safety. People can use it in food, drinks, and animal feed.

How does NORBIDAR ensure high purity?

NORBIDAR uses special ways to make and clean fumaric acid. They test every batch to make sure it is good. Their process gives fumaric acid that is over 99% pure.