Fumaric acid is produced using specific chemical reactions. These reactions transform the starting materials in a safe environment. Fumaric acid is crucial in food and beverages and is also used in animal feed, industrial products, and rosin paper adhesives. NORBIDAR supplies fumaric acid to numerous companies due to its versatility and consistent quality. This compound helps purify the air and can assist air purification equipment in factories. However, the use of fumaric acid produces dust and chemicals with a pungent odor.

- Food and Beverages Fumaric acid: Global Market Share 34.9%

- Industrial Grade Fumaric Acid: Global Market Share 36.2%

- Rosin Paper Adhesives: Global Market Share 10%

Key Takeaways

- Fumaric acid is crucial in food and beverages and is also used in industrial production. Understanding its uses helps to understand its importance.

- Safety is paramount when producing fumaric acid. Always wear protective equipment. Ensure good ventilation to prevent accidents.

- Choose the optimal fumaric acid preparation method. Maleic acid isomerization is a common preparation method that can produce fumaric acid in large quantities.

- Purity is critical! Please check the purity frequently to ensure the safety of fumaric acid for food and pharmaceuticals.

- When purchasing fumaric acid, choose suppliers with good certifications such as ISO and GMP to ensure its safety and quality.

Materials and Safety for Making Fumaric Acid

Chemicals and Equipment List

The preparation of fumaric acid requires careful planning. The process uses chemicals such as maleic acid, maleic anhydride, bromosuccinic acid, and thiourea. Each chemical plays a different role in the preparation of fumaric acid. Scientists also use distilled water, hydrochloric acid, and activated carbon to purify the product.

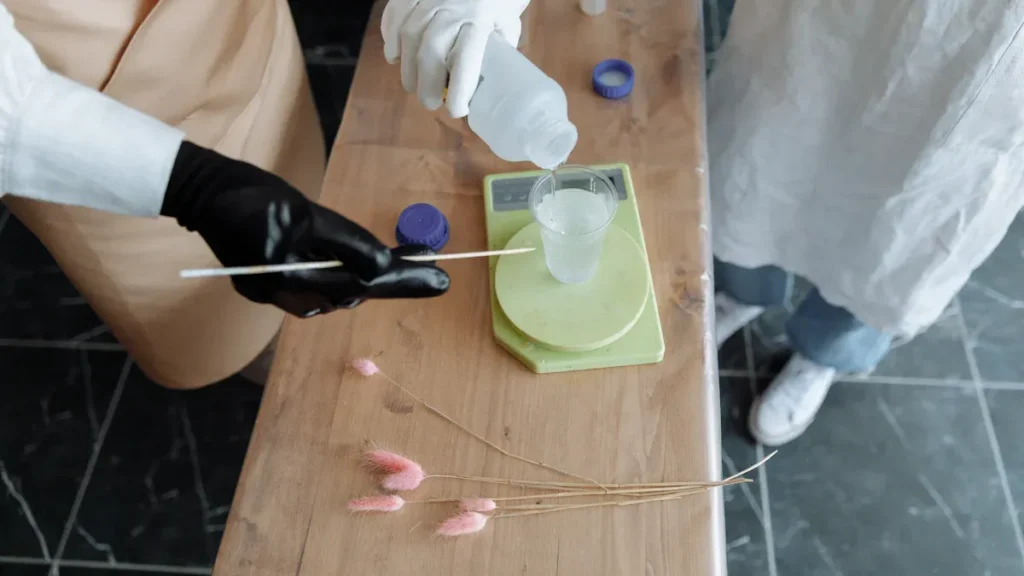

You will need glass beakers, flasks, stir bar, and a hot plate. A thermometer is used to monitor the temperature during the reaction. Filtration tools, such as Buchner funnels and filter paper, help separate fumaric acid crystals from the liquid. Safety goggles, gloves, and lab coats protect workers from spills and harmful gases. A fume hood removes harmful gases from the air.

Tip: Always label all containers and chemicals before starting the preparation of fumaric acid. This prevents errors and keeps the work area clean.

Safety Precautions

Safety is paramount when preparing fumaric acid. Workers must always wear safety equipment. Gloves protect hands from the potent chemicals. Safety goggles protect eyes from splashes. Lab coats protect skin and clothing. Fume hoods help remove strong odors and harmful gases.

Areas where fumaric acid is prepared require good air circulation. Workers must not eat or drink near the work area. Hands must be washed after handling chemicals. Emergency showers and eyewash stations should be available for unforeseen circumstances.

Regulations help ensure the safe preparation and use of fumaric acid. Many companies follow GMP and GLP guidelines to ensure their production processes comply with regulations. ISO certification means a company follows global quality standards. Food-grade fumaric acid must meet IP, BP, USP, or FCC standards. In the United States, food-grade fumaric acid requires STAR-K Kosher certification. The following table lists common certifications used in fumaric acid production:

| Certification Type | Description |

|---|---|

| GMP Certification | Certified companies that follow Good Manufacturing Practices. |

| GLP Certification | Compliant with Good Laboratory Practices. |

| ISO Certification | Compliant with global quality standards. |

| STAR-K Kosher | Required for US food products. |

| Fumaric Acid Standards | Compliant with IP/BP/USP/FCC food-grade standards. |

These standards ensure worker safety and guarantee that fumaric acid is suitable for food, animal feed, and industrial use.

How to Make Fumaric Acid: Main Methods

Fumaric acid plays an important role in many industries. Scientists synthesize fumaric acid in the laboratory using several main methods. Each method has its specific steps and required tools. The following table compares the most commonly used methods and their yields.

| Method | Description | Yield |

|---|---|---|

| Chemical Isomerization | Changes maleic acid into fumaric acid very well. | Over 80% |

| Biosynthesis | Uses tiny living things and special science. | Low yield |

Isomerization of Maleic Acid

Maleic acid isomerization is a classic method for preparing fumaric acid. In this process, maleic acid undergoes a configurational change to fumaric acid. Scientists use heating or catalysts to accelerate this conversion. The reaction takes place in water or other liquids. This method has a high yield, typically exceeding 80%. Many laboratories prefer this method because it is simple to operate and highly effective.

Note: Maintaining a suitable temperature helps to increase the yield of fumaric acid.

Thiourea-Catalyzed Conversion

Another method uses thiourea as an auxiliary agent. In this method, maleic acid reacts with thiourea in a liquid such as methanol. This reaction requires a relatively high temperature. Thiourea can accelerate the conversion. Observing the reaction reveals that it follows a specific pattern, with a conversion rate of approximately 1.41 for maleic acid and approximately 0.99 for thiourea. This method can convert approximately 90% of the starting material to fumaric acid, making it very effective.

From Bromosuccinic Acid

The method of preparing fumaric acid from bromosuccinic acid is also commonly used in laboratories. This method mainly consists of three steps:

| Step | Description |

|---|---|

| 1 | Heat bromosuccinic acid with water. |

| 2 | Add potassium hydroxide (KOH) to help the reaction. |

| 3 | Collect the fumaric acid that forms. |

If scientists use N-bromosuccinimide, benzoyl peroxide, and acetic acid, and heat for six hours, they can obtain fumaric acid with a purity of up to 90%. This method is very suitable when high-purity fumaric acid is required.

From Maleic Anhydride

The following methods are commonly used in factories and laboratories to prepare fumaric acid from maleic anhydride:

- Using a catalyst, maleic anhydride is prepared from hydrocarbon compounds.

- Maleic anhydride is converted to maleic acid with water.

- Maleic acid is converted to fumaric acid by heating or in the presence of a catalyst.

- The method of purifying fumaric acid is crystallization.

Scientists use mineral acids, peroxides, or thiourea as auxiliaries. The optimal reaction temperature is 145°C to 260°C. After the reaction, the product is cooled, filtered, washed, dried, and pulverized to obtain pure fumaric acid.

| Step | Description |

|---|---|

| 1 | Mix benzene or butene and air in a reactor. |

| 2 | Make maleic acid. |

| 3 | Change maleic acid into fumaric acid. |

| 4 | Cool, filter, wash, dry, and crush to get the final product. |

Tip: Using optimal auxiliaries and temperatures can produce more and higher quality fumaric acid.

Scientists are constantly working to improve these methods. New ideas utilize specialized microorganisms and novel reactor designs. For example, fermentation using Rhizopus mycelium can produce over 80 grams of fumaric acid per liter of glucose in 72 hours. Airlift reactors and bubble column reactors help reduce costs and make the production process more environmentally friendly. Some laboratories are even reusing mycelial balls to make the production process even greener.

These key methods help scientists and companies produce fumaric acid for a variety of uses. Each method has its own advantages, depending on the desired yield, purity, and batch size.

Fumaric Acid Yield and Purity Tips

Maximizing Yield

Scientists employ different methods to increase fumaric acid yield. They select optimal starting materials. They closely monitor reaction conditions. They help maleic acid convert to fumaric acid by altering temperature and pH. During fermentation, researchers use specific E. coli strains. These strains produce more fumaric acid. One strain, called FUM1.0, achieved a yield of 92% with the help of a specific enzyme. Lower intracellular ATP levels also contribute to the conversion of glucose to fumaric acid. Increasing the expression of the ppsA gene can slightly increase yield. These steps demonstrate that altering cellular composition and monitoring the production process helps produce more fumaric acid.

Tip: When preparing fumaric acid, always check the temperature and pH. Even small changes can help you get more product.

Troubleshooting Common Issues

Problems sometimes occur when preparing fumaric acid. Crystals may fail to form, or the product may appear contaminated. If crystals do not grow, check the cooling rate of the mixture. Try using different solvents. Slow cooling helps crystals grow larger and purer. If the product contains impurities, filter the solution again or use activated charcoal. If the fumaric acid yield is low, the temperature may be unsuitable. Adjusting the temperature and stirring the mixture thoroughly should resolve this issue. If the color is abnormal, wash the fumaric acid again with distilled water.

| Issue | Solution |

|---|---|

| No crystals | Cool slowly, try new solvent |

| Low yield | Change temperature, stir more |

| Impurities | Filter again, use charcoal |

| Off color | Wash with distilled water |

Purity Checks

Determining the purity of fumaric acid is crucial. This is important for the food, pharmaceutical, and industrial sectors. Scientists use thin-layer chromatography (TLC) to analyze samples. They dissolve fumaric acid in acetone and then compare it with a standard solution. The test uses silica gel GF 254 as a substrate. After spotting the sample, it is sequentially developed using formic acid, chloroform, butanol, and heptane. The TLC plate is dried at 100°C for 15 minutes. Scientists observe the spots under 254 nm UV light. The brightness of the fumaric acid spot should not exceed that of the standard spot, indicating an impurity content of less than 1.5%.

- Matrix: Silica gel GF 254

- Test solution: Fumaric acid in acetone

- Reference solution: Maleic acid and fumaric acid in acetone

- Developing agents: Formic acid, chloroform, butanol, heptane

- Detection: 254 nm UV light

- Limit: The brightness of the fumaric acid spot must not exceed that of the reference solution (1.5%)

Note: Regular purity testing helps ensure the safety and suitability of fumaric acid for various applications.

Fumaric Acid Purification

Purifying fumaric acid makes it safe and effective. Many industries require pure fumaric acid. Scientists use different steps to remove impurities and improve its quality. The main methods include recrystallization, decolorization, and sublimation. Each method helps bring fumaric acid to meet stringent standards applicable to the food, pharmaceutical, and industrial sectors.

Fumaric Acid Recrystallization Steps

Recrystallization is a common method for purifying fumaric acid. Scientists place coarse fumaric acid crystals into hot distilled water. They heat the mixture until the fumaric acid is completely dissolved. Then, they allow the solution to cool slowly. As the temperature decreases, pure fumaric acid crystals gradually grow. Workers collect the crystals by filtration and then dry them. Sometimes, using hot hydrochloric acid is more effective than using water. This method can remove many impurities, resulting in very pure fumaric acid.

| Method | Description |

|---|---|

| Recrystallization | Dissolve rough fumaric acid in hot water, cool, then collect pure crystals. |

| Decolorization | Use activated charcoal or other methods to remove color impurities. |

| Sublimation | Heat fumaric acid to vaporize and cool to form pure crystals. |

Fumaric Acid Decolorization

Decolorization removes unwanted color from fumaric acid. Activated charcoal is added to a hot solution. The activated charcoal adsorbs colored impurities. After stirring, the activated charcoal and impurities are filtered out. Sometimes, alkali metal salts or thiourea can also play a supporting role. The following are common decolorization steps:

- Place activated charcoal into a hot fumaric acid solution.

- Stir the mixture to allow the activated charcoal to adsorb the color.

- Filter the solution to remove activated charcoal and impurities.

- Cool the solution to allow pure fumaric acid crystals to grow.

- Collect and dry the crystals.

This process makes fumaric acid clear and transparent. This is crucial for the food and pharmaceutical industries.

Fumaric Acid Sublimation

Sublimation is another method for purifying fumaric acid. The fumaric acid is heated to vaporize. The vapor cools on a cold surface and forms pure crystals. Impurities remain in the crystals because they do not vaporize. This method is ideal for preparing high-purity fumaric acid. Scientists use sublimation for sensitive applications such as pharmaceuticals and scientific research.

NORBIDAR’s fumaric acid meets high standards. The product has a purity of 99.5-100.5%. Its impurity content is extremely low. Many industries trust NORBIDAR’s fumaric acid. They use it in food, animal nutrition, and various technical applications. The table below lists some quality standards for commercial fumaric acids:

| Quality Specification | Value |

|---|---|

| Assay (%) | 99.5-100.5 |

| Maleic acid by HPLC (%) | Max 0.1 |

| Loss on drying (%) | Max 0.5 |

| Residue on ignition (%) | Max 0.1 |

| Melting Range | 286 – 302 °F |

| Arsenic | Max 3 mg/kg |

| Lead | Max 2 mg/kg |

| Mercury | Max 1 mg/kg |

Tip: Always check the purity of fumaric acid after each step. High-purity fumaric acid performs better in the food, pharmaceutical, and industrial sectors.

Scientists synthesize fumaric acid using a multi-step process. First, they perform biotransformation. Next, they use acidification crystallization. Then, they employ precipitation. Afterward, they concentrate the fumaric acid through electrodialysis. Finally, they neutralize and dissolve it. Each step contributes to increasing the purity of the fumaric acid. Safety is paramount at every stage. Workers wear protective equipment and strictly adhere to operating procedures. This ensures the safety of fumaric acid in the food, animal feed, and pharmaceutical industries.

NORBIDAR offers high-quality fumaric acid with a wide range of applications. Their fumaric acid is non-hygroscopic, maintaining freshness in dry powder mixtures. It has a stronger acidic taste compared to other acidifiers. It helps inhibit bacteria in food. NORBIDAR’s fumaric acid is highly pure and safe. Many companies trust NORBIDAR for use in the food, animal feed, and pharmaceutical industries.

The correct way to purchase fumaric acid includes checking for compliance with ISO 9001, HACCP, GMP, REACH, and FDA standards. Buyers should request laboratory reports and obtain certificates for each batch of product. They should also conduct sample testing. The table below lists sources of high-quality fumaric acid suppliers:

| Region | Advantages |

|---|---|

| Shandong | Low production cost of fumaric acid, reasonable selling price. |

| Shaanxi | Biotechnology center produces high-purity bio-based fumaric acid. |

| Coastal Areas | Factory mainly focuses on export, convenient transportation. |

| Hebei & Jiangsu | Large-scale production of fumaric acid for food and animal feed. |

| Sichuan | Follows GMP standards for pharmaceuticals and health products. |

Tip: Readers can check the Frequently Asked Questions for help with purchasing fumaric acid.